Pulley Block Series

Backed by our prosperous industry acquaintance, we present a comprehensive range of Single Sheave Pulley Block. This product is available in varied sizes and designs that meet on customer’s demand.

Pulley Block Series Available

Single Sheave Pulley Block, Double Sheave Pulley Block, Trible Sheave Pulley Block, Hook & Hook Turnbuckles, Hook & Eye Turnbuckles, Connecting Link, Drop Forged Wire Rope Clips.

Single Sheave Pulley Block.

Sheave Dia (mm) |

Wire Rope Dia. (MM) |

SWL (tans) |

Test (tons) |

Weight (Kgs) |

8''(200) |

9~162 |

1 |

4 |

22 |

10” (250) |

14~16 |

3 |

12 |

28 |

12” (300) |

16~21 |

3 |

12 |

30 |

12”(300) |

16~21 |

5 |

20 |

33 |

14”(350 |

21~24 |

5 |

20 |

42 |

14”(350) |

24~29 |

8 |

32 |

50 |

16”(400) |

21~24 |

5 |

20 |

57 |

16”(400) |

25~29 |

8 |

32 |

69 |

16”(400) |

29~32 |

10 |

40 |

74 |

18” (450) |

29~36 |

10 |

40 |

97 |

18”(450) |

32~36 |

15 |

60 |

110 |

20” (500) |

38~42 |

20 |

80 |

180 |

Double Sheave Pulley Block

Sheave Dia (mm) |

Wire Rope Dia. (MM) |

SWL (tans) |

Test (tons) |

Weight (Kgs) |

10” (250) |

14~16 |

6 |

12 |

54 |

10”(250) |

14~16 |

8 |

16 |

60 |

10”(250) |

16~20 |

10 |

20 |

67 |

12” (300) |

16~20 |

10 |

20 |

73 |

12” (300) |

16~20 |

12 |

24 |

87 |

12” (300) |

21~24 |

15 |

30 |

94 |

14”(350) |

18~22 |

10 |

20 |

102 |

14”(350) |

20~24 |

15 |

30 |

110 |

14”(350) |

20~24 |

20 |

40 |

120 |

16”(400) |

24~28 |

20 |

40 |

142 |

16”(400) |

24~28 |

25 |

50 |

161 |

16”(400) |

28~32 |

30 |

60 |

186 |

16”(400) |

28~32 |

40 |

80 |

213 |

18” (450) |

28~32 |

25 |

50 |

209 |

18” (450) |

28~32 |

30 |

60 |

236 |

18” (450) |

28~32 |

40 |

80 |

272 |

20” (500) |

32~38 |

100 |

200 |

520 |

Trible Sheave Pulley Block

Sheave Dia (mm) |

Wire Rope Dia. (MM) |

SWL (tons) |

Test (tons) |

Weight (Kgs) |

10” (250) |

14~16 |

9 |

29 |

74 |

10” (250) |

14~16 |

12 |

32 |

80 |

10” (250) |

16~20 |

15 |

35 |

86 |

12” (300) |

16~20 |

14 |

34 |

117 |

12” (300) |

16~20 |

17 |

37 |

126 |

12” (300) |

20~24 |

20 |

40 |

141 |

14”(350) |

20~24 |

20 |

40 |

157 |

14”(350) |

20~24 |

25 |

45 |

176 |

14”(350) |

24~28 |

30 |

50 |

200 |

16”(400 |

24~28 |

30 |

50 |

234 |

16”(400 |

28~32 |

40 |

60 |

256 |

18” (450) |

28~32 |

40 |

60 |

360 |

20” (500) |

32~38 |

100 |

200 |

650 |

Hook & Hook Turnbuckles

Thread Dis.& Take |

Weight each LBS |

Working Load Limit |

A |

D |

E/Closed |

F |

J/Open |

K/Closed |

M/Open |

N/Closed |

BB |

1/4 x 4 |

0.30 |

4000 |

0.25 |

0.45 |

1.59 |

1.27 |

11.12 |

7.12 |

11.94 |

7.94 |

4.00 |

5/16x4‐1/2 |

0.47 |

7000 |

0.31 |

0.56 |

1.94 |

1.50 |

12.81 |

8.31 |

13.81 |

9.31 |

4.50 |

3/8 x 6 |

0.78 |

1000 |

0.38 |

0.56 |

2.30 |

1.77 |

16.50 |

10.50 |

17.72 |

11.72 |

6.00 |

½ x 6 |

1.60 |

1500 |

0.50 |

0.66 |

2.94 |

2.28 |

18.82 |

11.82 |

20.38 |

13.38 |

6.00 |

½ x 9 |

1.83 |

1500 |

0.50 |

0.66 |

2.94 |

2.28 |

24.82 |

14.82 |

26.38 |

16.38 |

9.00 |

½ x 12 |

2.28 |

1500 |

0.50 |

0.66 |

2.94 |

2.28 |

30.82 |

17.82 |

32.38 |

19.38 |

12.00 |

5/8 x 6 |

2.75 |

2250 |

0.63 |

0.90 |

3.69 |

2.81 |

20.50 |

13.25 |

22.50 |

15.25 |

6.00 |

5/8 x 9 |

3.38 |

2250 |

0.63 |

0.90 |

3.69 |

2.81 |

26.50 |

16.25 |

28.50 |

18.25 |

9.00 |

5/8 x 12 |

3.50 |

2250 |

0.63 |

0.90 |

3.69 |

2.81 |

32.50 |

19.25 |

34.50 |

21.25 |

12.00 |

3/4 x 6 |

3.89 |

3000 |

0.75 |

0.98 |

4.52 |

3.33 |

22.38 |

14.88 |

24.78 |

17.28 |

6.00 |

3/4 x 9 |

5.28 |

3000 |

0.75 |

0.98 |

4.52 |

3.33 |

28.38 |

17.88 |

30.78 |

20.28 |

9.00 |

3/4 x 12 |

5.43 |

3000 |

0.75 |

0.98 |

4.52 |

3.33 |

34.38 |

20.88 |

36.78 |

23.28 |

12.00 |

3/4 x 18 |

8.12 |

3000 |

0.75 |

0.98 |

4.52 |

3.33 |

46.38 |

26.88 |

48.78 |

29.28 |

18.00 |

7/8 x 12 |

8.10 |

4000 |

0.88 |

1.13 |

5.19 |

3.78 |

36.00 |

22.25 |

38.75 |

25.00 |

12.00 |

7/8 x 18 |

9.95 |

4000 |

0.88 |

1.13 |

5.19 |

3.78 |

48.00 |

28.25 |

50.75 |

31.00 |

18.00 |

1 x 6 |

9.33 |

5000 |

1.00 |

1.25 |

5.84 |

4.25 |

25.63 |

17.63 |

28.69 |

20.69 |

6.00 |

1 x 12 |

11.93 |

5000 |

1.00 |

1.25 |

5.84 |

4.25 |

37.63 |

23.63 |

40.69 |

26.69 |

12.00 |

1 x 18 |

14.00 |

5000 |

1.00 |

1.25 |

5.84 |

4.25 |

49.63 |

29.63 |

52.69 |

32.69 |

18.00 |

1 x 24 |

17.25 |

5000 |

1.00 |

1.25 |

5.84 |

4.25 |

61.63 |

35.63 |

64.69 |

38.69 |

24.00 |

1‐1/4 x 12 |

20.58 |

6500 |

1.25 |

1.50 |

7.22 |

5.13 |

40.44 |

25.94 |

44.06 |

29.56 |

12.00 |

1‐1/4 x 18 |

23.00 |

6500 |

1.25 |

1.50 |

7.22 |

5.13 |

52.44 |

31.94 |

56.06 |

35.56 |

18.00 |

1‐1/4 x 24 |

27.00 |

6500 |

1.25 |

1.50 |

7.22 |

5.13 |

64.44 |

37.94 |

68.06 |

41.56 |

24.00 |

1‐1/2 x 12 |

27.50 |

7500 |

1.50 |

1.88 |

8.34 |

5.75 |

43.94 |

28.94 |

47.44 |

32.44 |

12.00 |

1‐1/2 x 18 |

31.00 |

7500 |

1.50 |

1.88 |

8.34 |

5.75 |

55.96 |

34.94 |

59.44 |

38.44 |

18.00 |

1‐1/2 x 24 |

37.50 |

7500 |

1.50 |

1.88 |

8.34 |

5.75 |

67.94 |

40.94 |

71.44 |

44.44 |

24.00 |

Hook & Eye Turnbuckles

Thread Dis.& Take |

Working Load Limit |

Weight each LBS |

A |

D |

E/Closed |

F |

J/Open |

K/Closed |

M/Open |

S |

N/Closed |

BB |

1/4 x 4 |

400 |

0.29 |

0.25 |

1.59 |

1.27 |

11.46 |

7.46 |

12.09 |

0.34 |

1.79 |

4.00 |

|

5/16x4‐1/2 |

700 |

0.49 |

0.31 |

0.50 |

1.94 |

1.50 |

13.19 |

8.69 |

13.47 |

0.44 |

2.09 |

4.50 |

3/8 x 6 |

1000 |

0.78 |

0.38 |

0.56 |

2.30 |

1.77 |

16.98 |

10.98 |

17.94 |

0.53 |

2.52 |

6.00 |

½ x 6 |

1500 |

1.61 |

0.50 |

0.66 |

2.94 |

2.28 |

19.45 |

12.45 |

20.47 |

0.72 |

3.23 |

6.00 |

½ x 9 |

1500 |

1.85 |

0.50 |

0.66 |

2.94 |

2.28 |

25.45 |

15.45 |

26.67 |

0.72 |

3.23 |

9.00 |

½ x 12 |

1500 |

2.26 |

0.50 |

0.66 |

2.94 |

2.28 |

31.45 |

18.45 |

32.67 |

0.72 |

3.23 |

12.00 |

5/8 x 6 |

2250 |

2.70 |

0.63 |

0.90 |

3.69 |

2.81 |

21.96 |

13.96 |

22.72 |

0.88 |

3.90 |

6.00 |

5/8 x 9 |

2250 |

3.13 |

0.63 |

0.90 |

3.69 |

2.81 |

27.96 |

16.96 |

28.72 |

0.88 |

3.90 |

9.00 |

5/8 x 12 |

2250 |

3.78 |

0.63 |

0.90 |

3.69 |

2.81 |

33.21 |

19.96 |

34.72 |

0.88 |

3.90 |

12.00 |

3/4 x 6 |

3000 |

3.89 |

0.75 |

0.98 |

4.52 |

3.33 |

23.13 |

15.63 |

24.95 |

1.00 |

4.69 |

6.00 |

3/4 x 9 |

3000 |

4.61 |

0.75 |

0.98 |

4.52 |

3.33 |

29.13 |

18..63 |

30.95 |

1.00 |

4.69 |

9.00 |

3/4 x 12 |

3000 |

5.83 |

0.75 |

0.98 |

4.52 |

3.33 |

35.13 |

21.63 |

36.95 |

1.00 |

4.69 |

12.00 |

3/4 x 18 |

3000 |

6.33 |

0.75 |

0.98 |

4.52 |

3.33 |

47.13 |

27.63 |

48.95 |

1.00 |

4.69 |

18.00 |

7/8 x 12 |

4000 |

8.10 |

0.88 |

1.13 |

5.19 |

3.78 |

36.53 |

22.78 |

38.66 |

1.25 |

5.10 |

12.00 |

7/8 x 18 |

4000 |

9.95 |

0.88 |

1.13 |

5.19 |

3.78 |

48.53 |

28.78 |

50.66 |

1.25 |

5.10 |

18.00 |

1 x 6 |

5000 |

9.33 |

1.00 |

1.25 |

5.84 |

4.25 |

26.8 |

18.80 |

29.20 |

1.44 |

6.36 |

6.00 |

1 x 12 |

5000 |

11.93 |

1.00 |

1.25 |

5.84 |

4.25 |

38.8 |

24.80 |

41.20 |

1.44 |

6.36 |

12.00 |

1 x 18 |

5000 |

14.00 |

1.00 |

1.25 |

5.84 |

4.25 |

50.8 |

30.80 |

53.20 |

1.44 |

6.36 |

18.00 |

1 x 24 |

5000 |

17.25 |

1.00 |

1.25 |

5.84 |

4.25 |

62.8 |

36.80 |

65.20 |

1.44 |

6.36 |

24.00 |

1‐1/4 x 12 |

6500 |

19.00 |

1.25 |

1.50 |

7.22 |

5.13 |

41.63 |

27.13 |

44.56 |

1.81 |

7.72 |

12.00 |

Connecting Link

Item No. |

Weight/KG |

Wll/T |

B.L/T |

A mm |

Lmm |

Kmm |

Hmm |

1/4 |

0.13 |

1.59 |

6.35 |

16.5 |

67 |

51 |

8 |

5/16 |

0.15 |

2.04 |

8.16 |

17 |

78.5 |

58.5 |

10 |

3/8 |

0.33 |

3.22 |

12.88 |

22 |

87.6 |

63.5 |

12 |

1/2 |

0.76 |

5.44 |

21.76 |

28.5 |

115.5 |

85.5 |

15 |

5/8 |

1.30 |

8.21 |

32.84 |

33 |

143 |

106 |

18.5 |

3/4 |

2.27 |

12.84 |

51.36 |

41 |

162 |

116 |

23 |

7/8 |

3.4 |

15.51 |

62.05 |

50.5 |

188.5 |

136.5 |

26 |

1 |

5 |

21.64 |

86.55 |

57 |

214.5 |

152.5 |

31 |

1‐1/4 |

9.24 |

32.80 |

131.2 |

65 |

265 |

188 |

38 |

Drop Forged Wire Rope Clips

WLL/T |

Weight Per (100 LBS) |

A |

B |

C |

D |

E |

F |

G |

H |

1/8 |

6 |

0.22 |

0.72 |

0.44 |

0.47 |

0.37 |

0.38 |

0.81 |

0.99 |

3/16 |

10 |

0.25 |

0.97 |

0.56 |

0.59 |

0.50 |

0.44 |

0.94 |

1.18 |

1/4 |

19 |

0.31 |

1.03 |

0.50 |

0.75 |

0.66 |

0.56 |

1.19 |

1.43 |

5/16 |

28 |

0.38 |

1.38 |

0.75 |

0.88 |

0.73 |

0.69 |

1.31 |

1.66 |

3/8 |

48 |

0.44 |

1.50 |

0.75 |

1.00 |

0.91 |

0.75 |

1.63 |

1.94 |

7/16 |

78 |

0.50 |

1.88 |

1.00 |

1.19 |

1.13 |

0.88 |

1.91 |

2.28 |

½ |

80 |

0.50 |

1.88 |

1.00 |

1.19 |

1.13 |

0.88 |

1.91 |

2.28 |

9/16 |

109 |

0.56 |

2.25 |

1.25 |

1.31 |

1.34 |

0.94 |

2.06 |

2.50 |

5/8 |

110 |

0.56 |

2.25 |

1.25 |

1.31 |

1.34 |

0.94 |

2.06 |

2.50 |

3/4 |

142 |

0.62 |

2.75 |

1.44 |

1.50 |

1.39 |

1.06 |

2.25 |

2.84 |

7/8 |

212 |

0.75 |

3.12 |

1.62 |

1.75 |

1.58 |

1.25 |

2.44 |

3.16 |

1 |

252 |

0.75 |

3.50 |

1.81 |

1.88 |

1.77 |

1.25 |

2.63 |

3.47 |

1‐1/8 |

283 |

0.75 |

3.88 |

2.00 |

2.00 |

1.91 |

1.25 |

2.81 |

3.59 |

1‐1/4 |

438 |

0.88 |

4.44 |

2.22 |

2.31 |

2.17 |

1.44 |

3.13 |

4.13 |

1‐3/8 |

442 |

0.88 |

4.44 |

2.22 |

2.38 |

2.31 |

1.44 |

3.13 |

4.19 |

1‐1/2 |

544 |

0.88 |

4.94 |

2.38 |

2.59 |

2.44 |

1.44 |

3.41 |

4.44 |

1‐5/8 |

704 |

1.00 |

5.31 |

2.62 |

2.75 |

2.66 |

1.63 |

3.63 |

4.75 |

1‐3/4 |

934 |

1.13 |

5.75 |

2.75 |

306 |

2.92 |

1.81 |

3.81 |

5.24 |

2 |

1300 |

1.25 |

6.44 |

3.00 |

3.38 |

3.28 |

2.00 |

4.44 |

5.88 |

2‐1/4 |

1600 |

1.25 |

7.13 |

3.19 |

3.88 |

3.19 |

2.00 |

4.56 |

6.38 |

2‐1/2 |

1900 |

1.25 |

7.69 |

3.44 |

4.13 |

3.69 |

2.00 |

4.05 |

6.63 |

**2‐3/4 |

2300 |

1.25 |

8.31 |

3.56 |

4.38 |

4.88 |

2.00 |

5.00 |

6.88 |

3 |

3100 |

1.50 |

9.19 |

3.88 |

4.75 |

4.44 |

2.38 |

5.31 |

7.61 |

**3‐1/2 |

4000 |

1.50 |

10.75 |

4.50 |

5.50 |

6.00 |

2.38 |

6.19 |

8.38 |

Pulley Block Series

Chain Pully Block

Pully is the important tools for hoisting. It has simple structure and easy to use. It can change divection of pulley, steel, wire rope and high weight cargoes, especially series of pulley combind with windlass. mast and other lifting machinery. It widely used in installation and construction. It item from 0.5T to 32 T, and wheels not exceed ten. our lifting tools including hooks, chain lifting ring and handing beam. You can choose one according to your need.

Bush Type Manila Rope Pulley

Dia of Sheave |

Dia of Rope |

Single Sheave Capacity (Kg) |

Double Sheave Capacity (Kg) |

Trible Sheave Capacity (Kg) |

3‐1/2” |

1/2” |

210 |

250 |

290 |

4” |

5/8” |

220 |

300 |

400 |

4‐3/4” |

3/4” |

280 |

500 |

850 |

6” |

1” |

310 |

1000 |

1200 |

7” |

1‐1/4” |

500 |

1500 |

1800 |

8” |

1‐1/2” |

1000 |

2000 |

2500 |

(Bearing Type) Manila Rope Pulley Block C.I. Wheel Rorged Hock

Dia of Sheave |

Dia of Rope |

Single Sheave Capacity (Kg) |

Double Sheave Capacity (Kg) |

Trible Sheave Capacity (Kg) |

3‐1/2” |

1/2” |

210 |

250 |

290 |

4” |

5/8” |

220 |

300 |

400 |

4‐3/4” |

3/4” |

280 |

500 |

850 |

6” |

1” |

310 |

1000 |

1200 |

7” |

1‐1/4” |

500 |

1500 |

1800 |

8” |

1‐1/2” |

1000 |

2000 |

2500 |

Pipe Lifting Clamp.

Lifting Cap. Per Pair in Tons |

Jaw Opening (mm) |

Plate Thinkness (mm) |

2 |

35 |

16 |

3 |

40 |

20 |

5 |

50 |

25 |

10 |

60 |

36 |

20 |

75 |

45 |

Lifting Clamp Series

Vertical Steel Plate Lifting Clamp

Application : Lifting and Transporting steel plate vertically.

Range of working load : 1-16 T. One clamp is used in the tests but in real cases two or more clamps are recommended. Only one layer of late being lifted each time. Lifting more than one layer of plate is prohibited. The steel plate being lifting shall be kept away from crashing on any other objects. When lifting the steel plate, the handle must be turned up and turned down when unloading. The tested loads of DSQ 1, DSA2, DSQ3 & DSQ5 are all 2 times of working load limit, the minimum breaking load is 4 times of the working load limit.The tested loads of DSQ8, DSQ12, DSQ16 are 1.5 times of the working load limit, the minimum breaking load is 3 times of the working load limit.

Horizontal Steel Plate Lifting Clamp

This clamp is designed to lift and transport steel plate horizontally. Range of working load : 2 ‐ 10 T. Two clamp are used in the tests, but in real case four clamp are recommended. The levering beam is needed when the steel plate is too long Test loading is 2 times the Working Load Limit. Minimum breaking Load is 4 times the Working Load Limit.

Vertical Steel Plate Lifting Clamp

Art |

WELL t |

Tickness mm |

A mm |

B mm |

C mm |

D mm |

E mm |

F mm |

G mm |

H mm |

I mm |

Jaw open mm |

NW kg/pc |

DSQ1 |

1 |

0-16 |

59 |

12 |

16 |

45 |

30 |

120 |

72 |

270 |

155 |

50 |

3.5 |

DSQ2 |

2 |

0‐22 |

61 |

16 |

23 |

55 |

45 |

165 |

90 |

340 |

190 |

55 |

6.3 |

DSQ3 |

3 |

5‐30 |

72 |

16 |

28 |

60 |

55 |

195 |

110 |

374 |

227 |

370 |

10.5 |

DSQ5 |

5 |

16‐55 |

82 |

20 |

33 |

70 |

70 |

250 |

135 |

458 |

275 |

90 |

19.3 |

DSQ8 |

8 |

40‐80 |

100 |

25 |

40 |

80 |

80 |

345 |

175 |

565 |

370 |

130 |

40 |

DSQ12 |

12 |

50‐90 |

107 |

28 |

45 |

90 |

105 |

430 |

182 |

635 |

380 |

150 |

52 |

DSQ16 |

16 |

60‐100 |

107 |

41 |

50 |

100 |

115 |

455 |

200 |

650 |

410 |

160 |

55 |

Horizontal Steel Plate Lifting Clamp

Art |

WLL t/2 |

Tickness mm |

A mm |

B mm |

C mm |

D mm |

NW kg/pc |

DSQ2 |

2 |

0-20 |

127 |

154 |

58 |

29 |

2.6 |

DSQ3 |

3 |

0-30 |

152 |

187 |

64 |

31 |

4.0 |

DSQ5 |

5 |

20-60 |

220 |

289 |

70 |

54 |

7.8 |

DSQ8 |

8 |

50-100 |

276 |

369 |

86 |

59 |

15.7 |

DSQ10 |

10 |

60-125 |

310 |

432 |

86 |

61 |

19.5 |

Wire Rope Pulling Hoist & Magnetic Lifter Series

We are an acclaimed name to offer a wide range of quality proven Beam Clamps. Offered product is design and manufactured using optimum quality materials and highly advanced technology to meet the international quality standards.

Beam Clamp / Wire Rope Pulling Hoist / Magnetic lifter Series

Series Beam Clamp

Model |

Capacity |

I‐Beam width |

A mm |

B mm |

C mm |

D mm |

E mm |

F mm |

G mm |

H mm |

Weight |

||

Max. |

Min. |

Max. |

Min. |

||||||||||

SAM H1 |

1000 |

75‐230 |

278 |

183 |

380 |

64 |

4 |

217 |

90 |

150 |

26 |

19 |

3.5 |

SAM H2 |

2000 |

75‐230 |

278 |

183 |

380 |

76 |

6 |

217 |

90 |

150 |

26 |

21 |

4.5 |

SAM H3 |

3000 |

80‐320 |

356 |

220 |

500 |

100 |

8 |

277 |

145 |

220 |

50 |

23 |

9.5 |

SAM H5 |

5000 |

90‐320 |

356 |

220 |

500 |

112 |

10 |

277 |

145 |

220 |

47 |

29 |

11 |

SAM H10 |

10000 |

90‐320 |

356 |

220 |

500 |

120 |

12 |

285 |

160 |

230 |

52 |

39 |

16 |

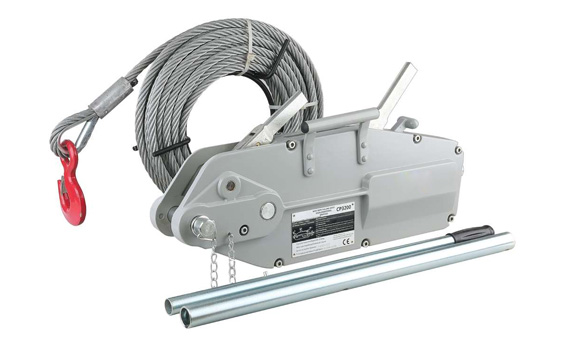

Wire Rope Pulling Hoist

Model |

Pulling Capacity |

Lifting Capacity |

Effort at full load |

Rope Ravel Strocke |

Wire R.Diameter |

Std.Fitting |

Overall Dimentions |

SAM ‐ 7 |

1250 |

750 |

30 |

40 |

08 |

Hook/Shackle |

500x250x100 |

SAM ‐ 15 |

2600 |

1600 |

40 |

45 |

12 |

Hook/Shackle |

575x350x150 |

SAM ‐ 20 |

3000 |

2000 |

42 |

45 |

12 |

Hook/Shackle |

575x350x150 |

SAM ‐ 50 |

8000 |

5000 |

60 |

25 |

20 |

Hook/Shackle |

800x450x190 |

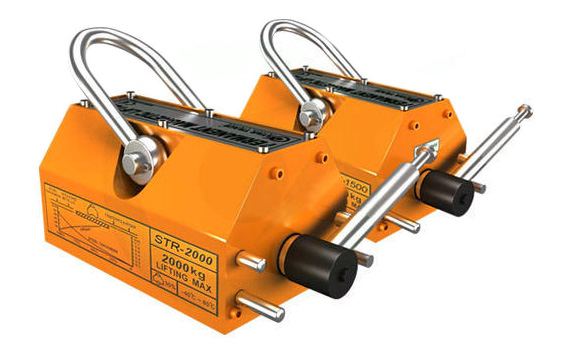

Permanent Magnetic Lifter

Type |

Lifting Capacity (kg) |

Dimension l*W*H (cm) |

Max. Breakaway force (Kg) |

Net Weight |

Gross Weight |

SAM ‐ 100 |

100 |

25*16*16 |

300 |

3 |

4 |

SAM ‐ 400 |

400 |

30*20*17 |

1200 |

10 |

11 |

SAM ‐ 600 |

600 |

37*23*21 |

1800 |

20 |

22 |

SAM ‐ 1000 |

1000 |

43*28*24 |

3000 |

37 |

40 |

SAM ‐ 2000 |

2000 |

52*30*31 |

5000 |

68 |

74 |

SAM ‐ 3000 |

3000 |

60*30*31 |

7500 |

87 |

93 |

SAM ‐ 4000 |

4000 |

68*30*41 |

10000 |

113 |

121 |

SAM ‐ 5000 |

5000 |

73*40*48 |

12500 |

198 |

213 |